Machining has always been about speed, precision and dependability, but in the highly competitive manufacturing world, efficiency is everything. The tools you choose to use impact your bottom line regardless of whether you’re producing components for aerospace, automotive components and high-tech electronic items. The indexable drill high-speed drill, the threading tools make a difference.

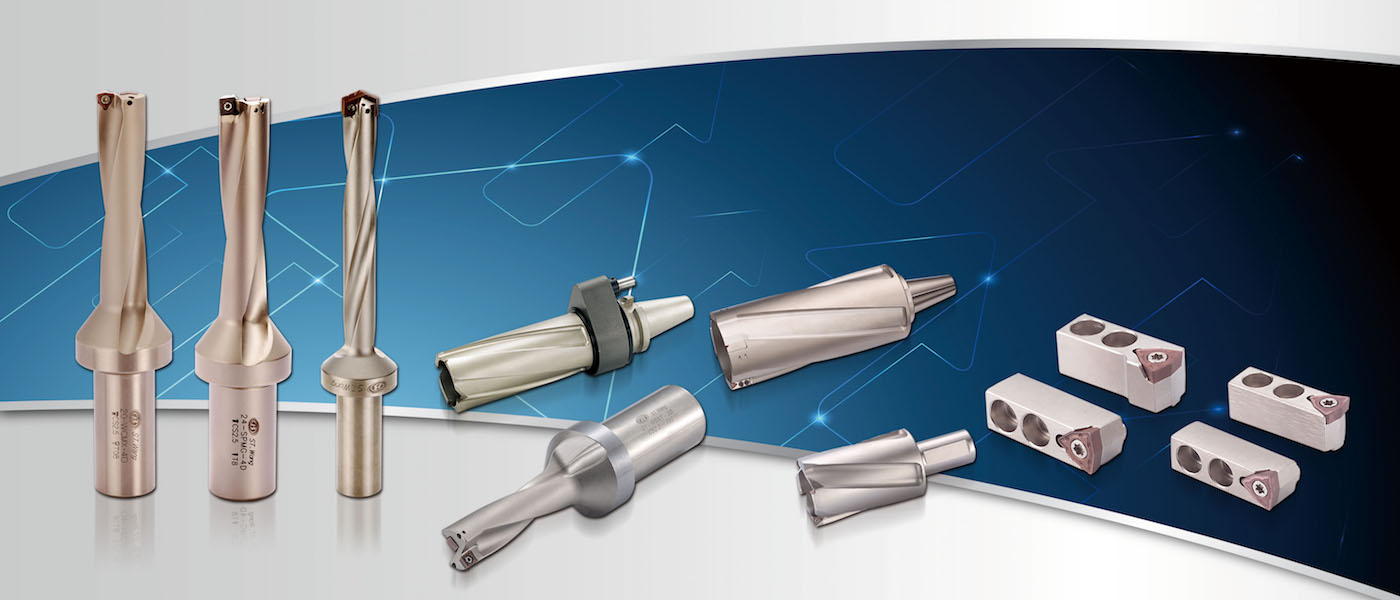

Image credit: stwang-tw.com

It’s not just an update to the old tools. They’re an intelligent way to minimize the time it takes to work, while also lowering costs and delivering superior results without a lot of effort. Have a look at every of them and see how they can help companies drill deeper, cleanly cut, and finish faster.

Indexable Drills: More Holes, Less Hassle

In the past, drilling large holes was expensive and time-consuming. The drills were prone to wear out, needed sharpening, and frequently slow production lines. Machine operators are increasingly using indexable drilling. Instead of replacing the entire tool when it becomes dull, you just switch out the cutting elements and then you’re back in business in minutes.

Indexable drills are recognized for their high efficiency. They’re built to last, have robust design and require very little maintenance. You can reduce use, keep your tools inventory low, and extend the lifespan of your equipment by using replaceable inserts. SHANG TZANG WANG ENTERPRISE CO., LTD, offers cutting-edge core-stay drills made of disposable material which provide reliable results in large-diameter machining. This upgrade could reduce downtime for shops that do repetitive hole machining.

High Speed Drills: Made to meet the demands of today.

In a production environment where time is money high-speed drills are made to run at a rapid pace without sacrificing precision. These drills work well with strong materials and rapid cycles. They can be used to make everything from large-volume automobile parts to precise medical components.

Modern high speed drills feature optimized flute designs and cutting-edge coatings that resist the build-up of heat, decrease friction, and extend tool life. It’s a result of less tool replacement with less breaking and more production. For any machinist who’s felt the frustration of a broken drill mid-cycle, switching to a high speed drill can feel like a revelation.

Tungsten Carbide End Mills: Reliable Performance Cut After Cut

In the realm of milling, tungsten carbide-based end mills are the mainstays of the workshop floor. They’re renowned for their durability and heat resistance as well as their ability to cut through hard materials without losing sharpness. These tools deliver consistently good results, whether finishing tiny corners or roughing up large areas.

The variety of tungsten carbide mills are what makes them unique. With a variety of flute counts, angles of helix and even coatings, they can be customized to suit a diverse array of tasks including titanium and aluminum. Carbide endmills are ideal for those who want to maintain precision while also being durable.

Threading Inserts: Tiny Tools, Big Impact

Threads’ creation might appear as a small part of the process, but this is one of the most vital aspects. A bad thread can ruin an otherwise excellent part. A top-quality insert is crucial. The small, reusable tools are made to cut internal or external threads with extreme accuracy and consistency.

In contrast to traditional dies and taps that wear unevenly, threading inserts offer steady results across many cycles. The tool can be indexed to the next cutting edge when one of the edges is dull. It’s not necessary to remove it or replace. It’s simple, cost-effective and easy to clean. Machinists not only love threading inserts due to their speed but also for their dependability. You can be sure that your threads will be able fit right the first time. There is no rework or rework, and there is no worry about rejecting parts.

The Bottom Line

Modern machining is highly time-sensitive. You shouldn’t waste it. That’s why today’s most efficient shops are shifting toward innovative, flexible tooling solutions. These advanced cutting tools don’t just increase precision; they also streamline workflows, reduce changeovers, and extend the life of usable tools. The result? The result? Less time spent on troubleshooting, and more time is spent in the creation of high-quality parts. In an industry with higher demands and lower margins manufacturers can be competitive through the use of tools that perform better.